Concrete Mold Casting Rubber

|

Product |

|

Density (kg/m3) |

Pot Life (min) |

TDS |

MSDS |

|

Concrete Mold Cast 30 |

980 |

25 |

|

||

|

Concrete Mold Cast 40 |

980 |

25 |

|||

|

Concrete Mold Cast 50 |

980 | 25 | |

Iso: |

Cestel liquid urethane mold rubbers are used for high volume stone production. Polyurethane mold cast rubber is strongly resistant against chemicals. It has negligible mold shrinkage and can be used for long years. Mold cast concrete rubber series has low viscosities that help to get smooth series. Cestel polyurethane cast resin has long pot-life that can be used in big mold making.

Our urethane rubber series are famous for their abrasion resistance and high tear strength. Mold Cast30 is the softest of our product and offers the most flexibility and is used for models with deep undercuts. It has superior abrasion resistance and tear strength and are ideal for casting concrete. These rubbers are used for casting of concrete.

Polyurethane resin usually stick well to the substrate. Therefore some porous surfaces like gypsum plasters, concrete, wood must be sealed before applying release agent. Shelf life of polyurethane resin is reduced after opening the lid. Therefore after opening the lid, it should be used as soon as possible. A suitable release agent must be used for demolding.

Cestel cast concrete mold rubber is cured a minimum of 20 – 24 hours at room temperature (23°C) before demolding. The reaction time can be shortened with mild heat. Lower temperature than 17 °C will leads to longer cure time and less physical properties and performance.

MEASURING & MIXING

Stir Part A before pouring. Weight A and B Part equally into a mixing cup (plastic, metal, or glass). Mix components 3 minutes with a metal or plastic tools until to get a homogenous liquid.

The mechnical stirrer can be used if large mixing quantities (bigger than 6 kg) are used. 3 minutes can be ideal to get a homogenously liquid.

Pour the mixture on your model. Avoid to entrapped air by pouring from the single spot slowly.

The mixture will be cured between 20-24 hours at room temperatures (23 Celcius). After 24 hours, the rubber can be demolded. In cold enviroment (less than 17 celcius) the cured rubber will have less physical properties. Therefore it is not suggested to cure the rubber at low temperatures. Avoid to add any catalyst in liquids to increase the curing rate. It can create more bubbles with less physical properties.

Important Notice:

Liquid polyurethanes are sensitive to moisture. It can absorb moisture from the air easily. It should be used as soon as possible when the A and B parts lid are opened. Wood mixing tools and containers can contain moisture. Therefore it is not suggested to use.

After mixing the A and B parts, vacuum can be used for the mixtures to remove the air bubbles. The components should be stored and used at room temperatures. Lower than room temperatures, the viscosities of components are increased. Higher viscosity materials trapped more air during the mixing.

It should be kept in mind that reaction rate is depend on temperature. In cold temperature (less than 17 celcius), the reaction rate will be slow and the rubber may not be cured completely. It can leads to low physical properties in rubber. Vice versa can be thought in higher temperature (above 23 celcius). The reaction rate between components will be faster. The chemical bonds will be completed less than 24 hours. However in much high temperatures, the pot life of the mixtures will be shorter. Therefore it may not give enough time to pour in big molds. The components A and B temperatures and the working conditions are very important to get a desired mold rubber. The annealing process can improve also physical properties of the rubber. Annealing is the post curing process at 60 celcius after 5 hours pouring the liquid components. This process makes stronger bond in chemical components than the regular curing. It is proved that annealing creates better physical properties than regular curing. If you have more detailed questions about annealing process, you can contact with our R&D via info@cestelkimya.com

How to avoid air bubbles from rubber

Air bubbles can depend also the urethane liquid formulation. Cestel liquid rubber is formulated to minimize the air trapped. In some cases, more air trapped in rubber. Usually in cold temperatures and high speed mixing, the air trapped more in liquid. Kept the components temperatures at 23 celcius. Mix the components at room temperatures in low humidty. Vacuum degassing at room temperatures will minimise the trapped air in the rubber. During the curing, slow rate air spraying on the liquid rubber will remove the bubbles.

Why should urethane rubber be used?

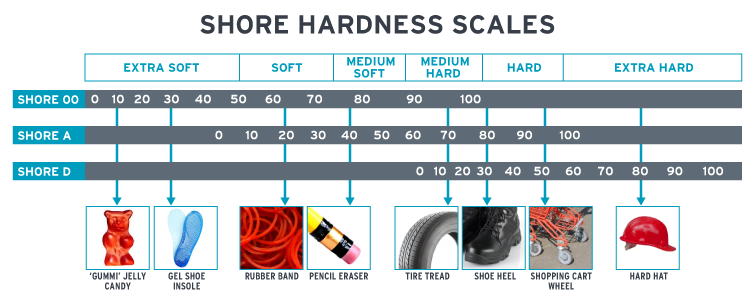

Urethane rubber can be formed in room temperatıre by mixing its two liquid components. There are many types of rubber from 10 shore A to 95 shore A. The cured product has higher physical properties. Liquid polyurethane rubber can be compared with liquid materials like RTV silicone. Both of them are flexible and can be mold in room temperature. However, urethanes have better chemical resistance compared to silicones. Its life time is longer than RTV silicone mold. It has better dimensional stabilities. There is no schrinkage and shearing. There is large range of hardness available in urethane resin. Polyurethane mold resin cost is much cheaper than RTV silicone resin.

Advantages Polyurethane Rubber

- There is more type of hardness range

- It is cheaper than silicone

- It does not need vacuum degassing

- It does not need accurate scale weight as in silicone

- It is used longer time than silicone

Disadvantages of Polyurethane Rubber

- Polyurethane resin sticks to most surfaces due to the its adhesive properties

- Release agent is needed before casting.

- Polyurethane has hydophilic properties. Therefore it can attract moisture from air that reacts with polyurethane.

- After opening, it should be used as soon as possible.

Basic informations about Mold and Casting

You can make of a mold anything you are interested in. If you want to make hobby molding, sculpted figure, toy, industrial figure, or any other mold, you will do first rubber mold. Rubber mold will enable you to reproduce any model exactly.

Mold is a negative impression taken from a positive model. Liquid model rubber takes the details of original model in design, texture and dimension. That makes a rubber mold to reproduce original model as the same as possible with the orginal one. Food designers, candle makers, special effects producers, automotive, shoe, furniture, construction industry use molds. Molds can be used endless variety of applications. You can make hundred or thousand exact reproductions of original model by using liquid rubber mold. Cestel rubber mold will help you to create your own model easily.

People have used mold thousands years ago from Ancient Egyptians to Chinese. Different types of mold materials like sand, clay, metal wax have been used to make mold At the present, these materials are replaced by silicone, polyurethane, latex and polysulfides.